We have expertise in designing and manufacturing devices such as steerable tools, guides, delivery systems, and catheters providing access and/or therapy delivery for structural heart, neurovascular, peripheral vascular, and electrophysiology procedures.

Complex

Delivery Systems

Manufacturing

& Line Transfer

Biosimulation

Lab & Testing

We specialize in the design, development, and manufacturing of complex, highly specialized catheters, steerable devices, and delivery systems for interventional markets. We’ve worked with partners on steerable balloon catheters, steerable neurovascular devices, and delivery devices for structural heart implants. As your vertically-integrated partner, we have the end-to-end services to guide you through the entire product development lifecycle.

Our cross-functional team and vertically integrated supply chain have expertise to provide comprehensive engineering support and final product solution.

We have expertise in producing microcatheters used in neurovascular, cardiovascular, and peripheral vascular applications. Our goal is to design and manufacture innovative products that provide better patient outcomes and advance the field of medical technology.

Our team has extensive experience designing, developing, and manufacturing these components and are dedicated to ensure that all our products meet regulatory requirements. We use advanced engineering and design software to create custom luers, handles, and hubs that are tailored to your specific medical device needs.

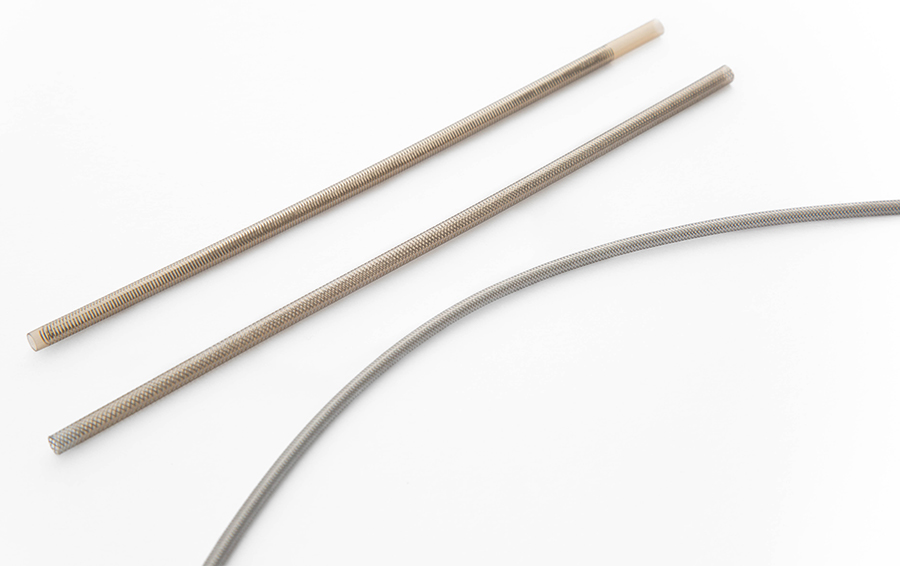

Braiding and coiling reinforcement techniques are used to optimize the catheter design to achieve the desired behavior and design requirements.

To achieve catheter tipping, Nextern uses advanced manufacturing techniques and technology, such as precision molding machines and glass dies that can create tips in a wide range of shapes and sizes.

Pad printing involves transferring ink from a silicone pad onto the surface of the component leaving behind a clear, precise, and permanent marking. This is a highly flexible and precise printing method that allows for the application of high-quality, multi-color graphics onto complex and irregularly shaped surfaces.

We specialize in niche medical instruments and devices to ensure accuracy and quality every time.

Manufacturability is a crucial aspect of commercially viable design; Nextern begins with this end in mind, making design transfer seamless. We maintain wholly-owned locations globally, which support our focus on tightly-controlled quality systems and supply-chain objectives.

Our range of finished devices includes assembly, packaging, sterilization management, and shipping, all aimed at ensuring your device reaches your customers seamlessly.

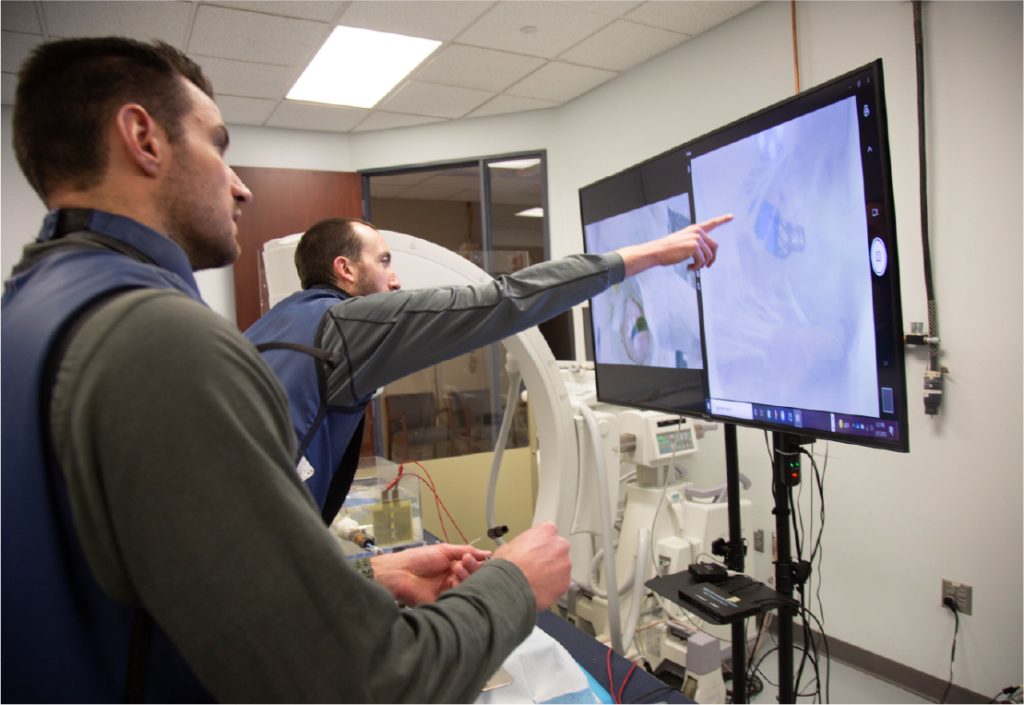

The services provided in the wet lab are designed to mimic life-like situations that can only truly be captured through hands-on practice in order to facilitate product development, physician training, and regulatory testing.

Complex

Delivery Systems

Manufacturing

& Line Transfer

Biosimulation

Lab & Testing

We specialize in the design, development, and manufacturing of complex, highly specialized catheters, steerable devices, and delivery systems for interventional markets. We’ve worked with partners on steerable balloon catheters, steerable neurovascular devices, and delivery devices for structural heart implants. As your vertically-integrated partner, we have the end-to-end services to guide you through the entire product development lifecycle.

Our cross-functional team and vertically integrated supply chain have expertise to provide comprehensive engineering support and final product solution.

We have expertise in producing microcatheters used in neurovascular, cardiovascular, and peripheral vascular applications. Our goal is to design and manufacture innovative products that provide better patient outcomes and advance the field of medical technology.

Our team has extensive experience designing, developing, and manufacturing these components and are dedicated to ensure that all our products meet regulatory requirements. We use advanced engineering and design software to create custom luers, handles, and hubs that are tailored to your specific medical device needs.

Braiding and coiling reinforcement techniques are used to optimize the catheter design to achieve the desired behavior and design requirements.

To achieve catheter tipping, Nextern uses advanced manufacturing techniques and technology, such as precision molding machines and glass dies that can create tips in a wide range of shapes and sizes.

Pad printing involves transferring ink from a silicone pad onto the surface of the component leaving behind a clear, precise, and permanent marking. This is a highly flexible and precise printing method that allows for the application of high-quality, multi-color graphics onto complex and irregularly shaped surfaces.

We specialize in niche medical instruments and devices to ensure accuracy and quality every time.

Manufacturability is a crucial aspect of commercially viable design; Nextern begins with this end in mind, making design transfer seamless. We maintain wholly-owned locations globally, which support our focus on tightly-controlled quality systems and supply-chain objectives.

Our range of finished devices includes assembly, packaging, sterilization management, and shipping, all aimed at ensuring your device reaches your customers seamlessly.

The services provided in the wet lab are designed to mimic life-like situations that can only truly be captured through hands-on practice in order to facilitate product development, physician training, and regulatory testing.

Begin a partnership with Nextern and gain experience and specialty capabilities for your medical device project.